Call at :

+86 18681515767

Call at :

+86 18681515767

Email :

marketing@jtspeedwork.com

Email :

marketing@jtspeedwork.com

Call at :

+86 18681515767

Call at :

+86 18681515767

Email :

marketing@jtspeedwork.com

Email :

marketing@jtspeedwork.com

RFID Technology Increases Transparency of Vehicle Weighing Management Process The unattended weighing management system adopts the long-distance RFID technology to realize the automatic identification function of the weighing vehicle on the original weighing management system, and merges the automatically collected weighing vehicle information into the weighing management system. The unattended weighing management system can increase the passing speed of the vehicle by 3-4 times at the metering office. Through the automatic identification and accurate measurement of the vehicle number, it can effectively prevent the economic loss caused by human fraud to the enterprise. After the implementation of the system, the labor intensity of the staff and the error rate of manual weighing have been greatly reduced, the transparency of the management process has been improved, and the informatization process of the enterprise has been promoted. RFID technology has improved the transparency of the vehicle weighing management process . Features of RFID Vehicle Weighing System 1. Quickly and automatically identify weighing vehicle information, improve identification efficiency, and alleviate the phenomenon of vehicles queuing and weighing; 2. RFID long-distance automatic identification, accurate data, and avoid manual management loopholes; 3. RFID reader uses outdoor Waterproof design ensures long-term stable operation; 4. RFID long-distance card reader has rich data transmission interfaces, which can realize data linkage with gates, cameras, etc. Vehicle weighing management system has been an important part of information management in coal mines, garbage dumps, petroleum industry, and non-ferrous metal mines. Undoubtedly, it will provide a brand new solution for these industries and form a new weighing management mode that is efficient, accurate, fast and anti-cheating. Shenzhen Osda Electronics Co., Ltd. has launched a smart car weighing system integrating computer technology, short-range microwave communication technology, image digital processing technology, and automatic control technology to realize automatic vehicle identification and information management, improve vehicle traffic efficiency and Security, and statistics of vehicle entry and exit data, convenient for management personnel to schedule, to reduce the labor intensity of management personnel, and effectively prevent charging loopholes. The vehicle weighing management system has become an important part of the information management of many enterprises, forming a new weighing management mode that is efficient, accurate, fast and anti-cheating. The traditional vehicle management mode: the vehicle needs to be parked and registered when it arrives at the factory. After the registration is completed, it is weighed, and then the vehicle number, unit, product name and other data are manually entered into the computer, and then measured. The whole process is time-consuming and aggravating. In order...

RFID Enables Animal Husbandry to Implement More Efficient and Intelligent Management Animal husbandry combines RFID technology to realize the automation and intelligent management of animal husbandry. Especially in large farms, the number of farmed animals has been perplexing every farmer. Relying on manual counting and statistics can easily cause data inaccuracy. precise. The soft design of the rfid animal husbandry management system from traditional livestock farm management to rfid technology management reflects a process in which technology changes the state of breeding. RFID enables animal husbandry to implement more efficient and intelligent management. RFID technology is mainly used in the feeding link in animal husbandry management, including intelligent weighing, intelligent feeding, intelligent identification and inventory, animal breeding, epidemic prevention and control management, etc. The advantages of RFID technology in animal husbandry management are gradually highlighted. Many large pig, cattle and sheep farming enterprises use RFID tag technology to manage animals. In this technology, the animal tag is mainly used for wireless communication with the reader, the animal tag is worn on the animal's ear, and the tag carries the animal's identity information. The reader can identify, track and exchange the data on the animal tags, so as to automatically identify and track animals, and achieve the purpose of scientific breeding and intelligent management. 1. Intelligent weighing By installing the RFID electronic tag animal ear tag identification reader in the animal weighing channel or automatic weighing machine, when the animal passes through the weighing channel or the automatic weighing machine, the RFID reader automatically collects the ear tag information and sends it to the automatic weighing machine. The weight data is uploaded to the terminal system. Simplify the work of measuring animal weight and obtain all animal weight data at one time, so as to better adjust the feeding management strategy, and the staged evaluation of the growth of fattening pigs will also be more accurate (compared to the traditional visual evaluation method. 2. Intelligent feeding By installing the RFID electronic tag animal ear recognition reader in the feeding trough, when the animal drinks and eats, it will be identified according to the animal weight information and repeated feeding information, and the corresponding water intake and feed amount will be fed to achieve scientific feeding. Reduce unnecessary feed waste. 3. Intelligent identification and inventory Animals wear RFID electronic tag ear tags, and the RFID electronic tag ear tag identification reader is installed in the access door or in the breeding pen. When animals pass through the passage gate or feeding pen, they can be automatically counted, and the collected information can be uploaded to the terminal management background in real time for data aggregation. The RFID feeding pen and...

RFID technology solves the problem of anti-counterfeiting and anti-smuggling in the clothing industry In recent years, with the rise of various new brands in the clothing industry, the market has gradually expanded, and the popularity of the e-commerce industry has led to the closure of many well-known brand clothing stores or the cancellation of directly-operated stores. The old brand also has certain problems in the maintenance of customers. After all, in the huge market, it will not always be a clear stream of regular sales, and fake goods and fake goods are not uncommon. If you were a business owner, what would you do? In fact, it is completely possible to solve the problem of anti-counterfeiting and anti-smuggling through RFID technology, and apply RFID electronic tags to clothing. The RFID tag chip can collect and store information, record sales trends, and quickly view sales trends for that product. At the same time, the code of the RFID tag is the only code in the world, which can effectively solve the problem of anti-counterfeiting and anti-channeling of enterprises! Easy and fast reading: data reading does not require a light source and can even be carried out through the outer packaging. When using a passive tag without its own battery, the effective identification distance can reach 1-8 meters; Fast recognition speed: as soon as the electronic tag enters the magnetic field or electromagnetic wave emission range, the UHF reader can immediately read the information in it, and can process multiple tags at the same time to realize batch identification; Large data capacity: The two-dimensional barcode with the largest data capacity can only store up to 2725 numbers; if it contains letters, the storage capacity is small; RFID tags can be expanded to 1K according to user needs; Long service life and wide application range: its radio communication method enables it to be used in highly polluted environments such as dust and oil pollution and radioactive environments, and its closed packaging makes its service life much longer than that of printed barcodes; Tag data can be dynamically changed: the data can be changed to be written using the programmer, giving the RFID label the function of an interactive portable data file, and the writing time is less than that of printing a barcode; Better safety: Not only passive tags with their own batteries, but also passive tags with their own batteries can be used. The rapid development of the market economy has promoted the diversity and richness of market products, satisfying the growing consumption of consumers. need. But at the same time, the problem is becoming more and more obvious. The large number of counterfeit and counterfeit products has seriously affected the interests of consumers and businesses. Branded apparel companies are constantly looking for new ways to promote and protect their brands and products. Because of its special technology, RFID gradually shows its practical value and perfe...

RFID Greatly Improves Logistics Sorting Efficiency And Accuracy Project background introduction: With the increasing scale of online shopping, the development of the logistics industry is becoming more and more prosperous, and logistics companies have higher and higher requirements for the average daily throughput and operating efficiency of super-large warehouses. This is a huge test for the operation and management of warehouses, especially It is a high-frequency inbound and outbound operation of large-scale goods. It is urgent to greatly improve the efficiency and at the same time ensure the accuracy of the data and information. With the increasingly fierce competition among logistics companies, whether they can be better than their competitors in warehouse operation efficiency plays a crucial role in seizing market opportunities. The pure manual mode of traditional logistics warehouses has already become more efficient in terms of efficiency. To increase to the upper limit, only by transforming the traditional logistics warehouse model with the help of emerging technologies such as the Internet of Things and big data, can the operational efficiency be further greatly improved and the old upper limit be broken. In order to realize the automation and digitization of the operation of large-scale logistics warehouses, more and more logistics enterprises have put forward to us the need for intelligent digital transformation of the inbound and outbound links of logistics warehouses. Project design goals 1. With the help of RFID technology, realize the intelligent and digitalization of warehouse entry and exit; 2. Improve overall operational efficiency and reduce labor costs; 3. Realize the automatic collection, storage and management of data, and visualize it to provide data support for operational decision-making; 4. Connect with the customer's original WMS, ERP and other business systems, and provide a complete and replicable overall solution. Project requirements 1. In response to the customer's urgent need to improve the efficiency of warehousing and warehousing, realize the warehousing and warehousing capacity of large volumes and high speed; 2. Automatically count and check documents to avoid manual errors and improve the accuracy of inbound and outbound data information; 3. Real-time presentation of inbound and outbound data, and upload and storage to realize the visualization of operations in the library; 4. Automatically record all operational behaviors, and connect to the customer's WMS and ERP systems to achieve traceable query of process records. Project specific plan Large-scale logistics warehouses of logistics companies have huge scale and high frequency of daily inbound and outbound warehouses. It is necessary to ensure the accuracy of inbound and outbound data while improving the speed of inbound and outbound inventory and the volume of a single inventory. According to the needs of customers, we provide customers with high-performa...

Through the establishment of a community card system, the system distributes a composite personnel electronic tag to each elderly person and staff member, which has comprehensive functions such as identity authentication, credit card consumption, access control management, and emergency rescue positioning. The personnel positioning system incorporates the indoor and outdoor areas of the entire community into the monitoring range of the wireless rescue network. When the elderly encounter difficulties anywhere in the community, when the emergency rescue button on the carry-on card is pressed, the computer screen of the on-duty personnel in the monitoring center will immediately display the emergency rescue button. The location of the elderly, as well as relevant information such as their personal health status and previous diseases, provide guidance for medical staff to respond quickly and seek emergency help. At the same time, it can also monitor and monitor the real-time location of the staff for standardized management and reasonable scheduling. The system consists of key equipment such as "reader", "dual-frequency personnel electronic tag", "server", "positioning database" and "application software". The basic positioning process is as follows: a) Arrange a certain number of readers in the installation distribution map in the community, and the number of readers is determined by the required coverage and positioning accuracy; b) Connect each reader to the background location server through Ethernet to form a wireless location network; c) Place reference electronic tags for positioning in the community ; d) Allocate dual-frequency personnel electronic tags to the elderly and staff, and establish a one-to-one correspondence between "tags" and "persons"; e) Install and run the positioning software on the server, and the positioning data can be directly written into the database or integrated into other systems. System functions Real time monitoring Display icons on the map corresponding to the person or thing the tag is bound to; Real-time monitoring of tags and display of the current location of tags in the map; The label flashes to indicate an alarm; Tabs are grouped, displayed with different icons; During the positioning process, the icon can be seen moving smoothly in real time; The specified label can be tracked, and the map automatically switches with the movement of the label; Move the mouse over the icon to see the information and status of the icon; Detailed information can be displayed after clicking on the icon; You can manually switch the map to view the activity of all labels on the specified map; The map can be zoomed in and out, adjusted to a suitable size; The map automatically switches floors when tracking a single ta...

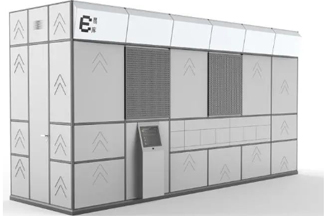

Chengdu Metro introduces smart mobile warehouses to create a new "smart Chengdu" RFID application scenario Recently, in response to the construction of "Smart Chengdu", Chengdu Metro introduced a new generation of supply chain infrastructure - RFID smart mobile warehouse in the TOD project of Sichuan Normal University. Once unveiled, the RFID smart mobile warehouse has attracted the attention of many netizens. What is RFID "Smart Mobile Warehouse"? The entire warehouse body of "RFID intelligent mobile warehouse" is composed of containers, which can be moved at any time according to the changes of the construction site, which is convenient for the project to configure the warehouse nearby and shorten the distance of material collection. Realize "where the construction is, the warehouse is there". The warehouse integrates a large number of smart devices such as RFID smart shelves, unmanned containers, temperature and humidity sensors, cameras, and IoT sensors, which can be used to store high-frequency materials commonly used on construction sites. At the same time, the AI face recognition function is added according to the pre-configured receiving list according to the type of work, and workers can automatically open it to receive materials. RFID "smart mobile warehouse", as the main starting point of digital warehouse management solutions, integrates digital technology with infrastructure to achieve precise management of project materials, thereby reducing service costs and maintenance costs in supply chain management. RFID "smart mobile warehouse" promotes digital and intelligent management Due to the particularity of the construction industry, most construction projects will set up material warehouses on the construction site, and reserve certain high-frequency consumables to facilitate workers to receive materials in stages. However, in the traditional material management mode, the material administrator can only register the purchase, storage, and material out of the warehouse through manual bookkeeping. In this way, there are problems such as inaccurate procurement plans, unreasonable inventory settings, inaccurate consumption, staff redundancy, and capital occupation. Through the combination of "smart shelves + unmanned containers", the RFID smart mobile warehouse has changed the previous situation of limited placement of warehouse materials and disordered management. The data kanban displays and records real-time data such as the quantity in the warehouse, the total amount used, and the user, which reduces manual accounting, improves the accuracy of accounting, and precisely controls costs. In addition, through the coexistence of the "order + consignment delivery" model, 24-hour unattended intelligent management enables seamless connection between performance delivery and agency operation, and realizes the inversion of the procurement process of high-frequency consumables. Efficiency, solve the backlog of inventory, and reduce the pressure ...

Since the Internet came into people's lives, and great changes have taken place in people's lives. Continuous innovation is of course with high-tech.When putting forward to the high-tech, We will think the Internet, When talking about the internet,we will think about the Internet of things RFID technology. Today we'll talk about RFID technology to retail what changed? Perhaps you will ask why about the only retail, that's because this year's news in the retail industry, so we'll talk about this so popular retail RFID technology has changed?Perhaps you will ask why about the only retail, that's because this year's news in the retail industry, so we'll talk about this so popular retail RFID technology has changed? 1. From a consumer perspective, It saves queuing time for clearing, improving the consumer experience. 2.From a staff perspective, It reduce the time wasted on counting merchandise, improve work efficiency. 3. From the angle of opening hours, it extended operating hours, but an unmanned operating mode. 5. From a stock perspective, the staff can learn in real time inventory and merchandise store location, and consumers can know in advance of inventory to stimulate consumption. 5. From the security perspective, you can reduce the waste of resources, integrated label to functionality that you implement in an tag. Is a label to cover all the information you need

In recent years, the domestic drug safety incidents frequently, drug electronic supervision and cause the heat of people. In March 2010, Shandong vaccine incident was exposed, because the vaccine in the cold chain transport and distribution links of the lack of regulation, resulting in untreated vaccines through illegal channels to 24 provinces and cities, illegal involving up to 570 million yuan. This event is the drug electronic supervision pushed to the cusp. "Temperature sensor tag" is for the cold chain of medicine "pain point", part of the cold chain transport equipment and monitoring equipment can be combined with the identification of the passive temperature sensitive electronic labels attached to the smallest package of the vaccine, And as a data collection point, the regulation from the ambient temperature to the object itself. In addition, the "temperature sensor tag" can also achieve real-time data communication, real-time acquisition, real-time warning, over-temperature alarm, the whole traceability purposes, to prevent data tampering, fraud and other events. According to the news, in recent years exposure of a series of vaccine problems, most of them are due to cold chain out of control, supervision out of control caused. At present, the monitoring mode of medicine cold chain market is mainly to monitor the ambient temperature, and it is difficult to establish effective connection between the monitoring point and the single object under test to form the supervision loophole. The "core" of the "temperature sensing tag" is a passive UHF RFID temperature sensor chip embedded in the tag, 3 mm long and 2 mm wide. It is in the field of intelligent identification function, but also a micro-wireless temperature sensor, with a lightweight, without battery, high precision and long-range temperature and so on. "Temperature sensor tag" can be attached to the surface of various objects, high-volume items for each single product for wireless, continuous, real-time temperature monitoring, applicable to cold chain logistics, power equipment safety monitoring, railway traffic safety , Human and animal body temperature monitoring, cultural and cultural collections, smart home appliances and other applications. "Temperature sensor electronic tag" is for the cold chain of medicine, "pain point" to achieve a part of the cold chain transport equipment and monitoring equipment combined. Cold chain regulation is based on passive temperature sensing electronic tags as a data collection point, the regulation from the ambient temperature to the object itself. This is to determine the single vaccine ID (identity identification number) at the same time, to achieve the temperature monitoring of the vaccine, to the medical cold chain on the 'double insurance'. In addition, the "temperature sensor electronic tag" can also real-time data communication, real-time acquisition, real-time warning, over-temperature alarm, the whole traceability purposes, to pr...

Categories

New Products

JT-6210 0-1m UHF RFID Desktop USB Reader Writer ISO18000-6C Read More

JT-7100 0-3m 860-960MHz UHF RFID Industrial Grade RFID Reader Read More

JT-8380 0-6m UHF RFID 860-960MHz Middle Range Integrated Reader Read More

JT-P983 Industrial Tablet Pad RFID Handheld Reader Grade Long Range Android UHF Terminal Bluetooth RFID Reader For Warehouse Read More

JT-1550 Small Mini HF RFID 13.56MHz Module ISO14443A ISO 15693 Protocol Read More

JT-2302A 13.56MHz RFID Module ISO14443A ISO15693 Protocol Read More

JT-2302 HF RFID 13.56MHz Module ISO14443A ISO15693 Support Mifare1 IC card Read More

JT-2540 TM200 UHF RFID 4-port Module 860-960MHz TTL Read More

Copyright © 2026 Shenzhen Jietong Technology Co.,Ltd. All Rights Reserved.

IPv6 network supported