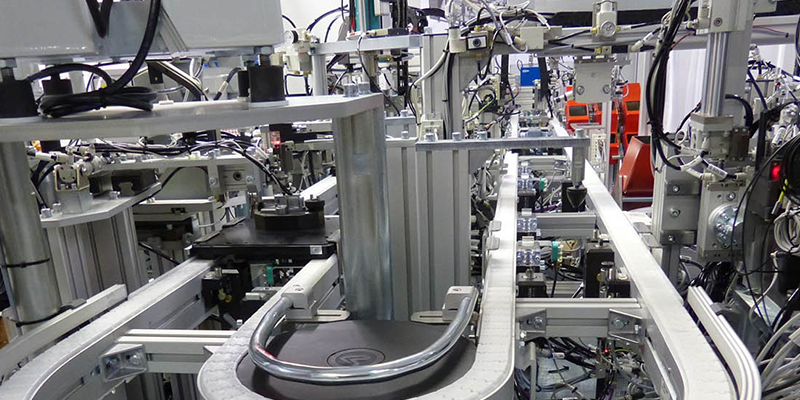

Achieve Precision and Real-Time Control on Your Production Line

Accurate knowledge of each component's location and status is critical to an efficient manufacturing process. However, many factories still depend on manual logs and paper-based systems, leading to production bottlenecks, misidentified inventories, and delivery delays. By the time a workflow anomaly is discovered, it has often already disrupted the entire production schedule. With inventory management solutions built by JTSPEEDWORK partners, gain real-time, automated visibility into every workstation, component, and product-in-progress.

English

English