Call at :

+86 18681515767

Call at :

+86 18681515767

Email :

marketing@jtspeedwork.com

Email :

marketing@jtspeedwork.com

Call at :

+86 18681515767

Call at :

+86 18681515767

Email :

marketing@jtspeedwork.com

Email :

marketing@jtspeedwork.com

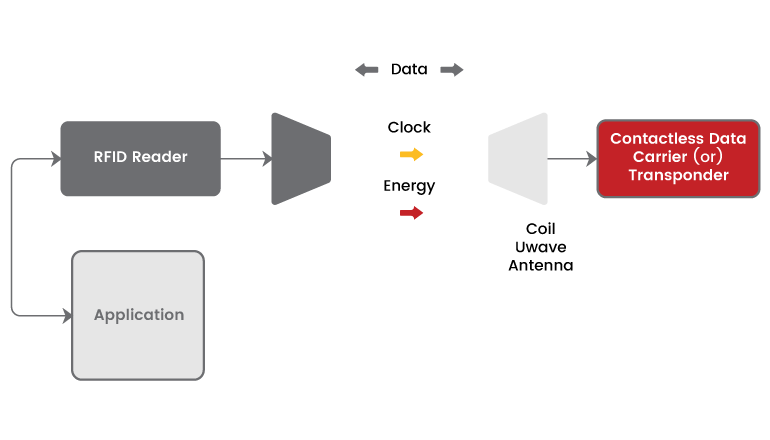

As technology rapidly evolves, various industries are leveraging innovative solutions to improve operational efficiency and enhance user experiences. In large-scale events such as concerts and sports games, where massive crowds need to be managed, RFID (Radio Frequency Identification) technology has become increasingly prevalent. It is transforming access control systems, ticket management, and on-site crowd flow management. This article delves into how RFID technology enhances smart ticketing, optimizes crowd management, and improves both event security and attendee experience. 1. Overview of RFID Technology RFID stands for Radio Frequency Identification, a technology that enables wireless, contactless data transmission and identification using radio waves. An RFID system typically consists of three components: a tag, a reader, and a backend database. The RFID tag contains a microchip and an antenna, which store a unique identification number; the reader uses radio waves to interact with the tag and transmit the data to the backend system for processing. The key advantages of RFID technology include contactless operation, long-range identification, and fast data transfer. These features make it ideal for applications in event access control, ticket management, asset tracking, and more. 2. Applications of RFID in Concert and Event Access Control For large-scale events such as concerts, music festivals, and sports games, managing access control is crucial for ensuring both security and smooth event flow. Traditional ticketing systems, such as paper tickets or QR codes, suffer from issues such as slow processing times, long queues, and vulnerabilities to ticket fraud. RFID technology effectively addresses these challenges. 1. Faster Entry and Reduced Queuing Time RFID-based access control systems embed RFID tags into tickets or wristbands, allowing attendees to quickly pass through access gates by simply presenting their RFID-enabled ticket or wristband. This contactless, rapid recognition process significantly reduces waiting times at entry points, easing the bottleneck that often occurs with traditional ticket scanning methods, and improving the overall efficiency of the event. 2. Enhanced Security and Ticket Authenticity RFID technology enables each ticket to have a unique ID, making it impossible to duplicate or forge the ticket. The embedded RFID tag provides each ticket with a unique identifier, which can be easily verified at the access point. This effectively prevents counterfeit tickets from being used, thereby ensuring the event’s security and reducing the risk of unauthorized access. 3. Multi-Level Access Control At large-scale events, there are often different levels of access, such as VIP tickets, staff credentials, and media passes. RFID technology allows for seamless implementation of tiered access controls, where different types of RFID tags can be assigned to various groups of attendees. The system automatically identifies and gran...

With the rapid development of global air logistics, diversified scenarios such as cross-border e-commerce, fresh food air transport, and high-end manufacturing components are placing higher demands on timeliness and accuracy. Traditional cargo tracking systems in aviation logistics often rely on barcodes, manual input, or GPS-based container tracking, which suffer from delays, inaccuracies, and high human involvement. Radio Frequency Identification (RFID) technology, with its contactless reading, fast identification, and automation features, is emerging as a key enabler of precise delivery in air freight logistics. I. Advantages of RFID in Air Freight RFID (Radio Frequency Identification) is an automatic identification technology that recognizes target objects and retrieves relevant data via radio waves. In air freight, RFID tags are typically attached to cargo, pallets, or containers and are read by readers to collect and transmit data. Key advantages of RFID include: Contactless and Efficient Reading: RFID tags can be identified from a distance without the need for line-of-sight, making it suitable for high-speed, high-volume sorting operations. Real-Time Data Updates: Information about cargo movement across various stages—transportation, storage, security checks—is continuously updated, ensuring seamless tracking. Durability in Harsh Environments: Unlike barcodes, RFID tags are resistant to dirt, scratches, and environmental stress, making them ideal for airport conditions. Simultaneous Multi-Tag Reading: RFID readers can scan multiple items at once, eliminating delays and errors common in manual scanning. Programmability and Data Storage: RFID tags can store more than just a unique ID; they can include weight, origin, destination, and special handling instructions. II. Key Application Scenarios in Air Freight Logistics RFID can be applied across the entire air freight process—from cargo registration and identity verification to security inspection, warehousing, flight tracking, and final delivery. 1. Cargo Registration and Identification At the origin, RFID tags are encoded by the shipper or airline, capturing detailed cargo information. Once generated, the tag’s unique ID accompanies the shipment throughout its journey, minimizing issues like mislabeling or misrouting. 2. Security Screening and Load Planning RFID systems can be integrated with airport security checks to verify cargo origin, documentation, and whether any restricted items are present. As goods move through inspection conveyors, RFID readers match them with digital manifests. Combined with aircraft loading systems, RFID helps optimize cargo loading sequence and safety. 3. Flight Segment Tracking During takeoff, layovers, and transit points, RFID enables real-time logging of each segment. For example, a shipment moving from Location A to C via B will have automatic logs for loading, arrival, and unloading events, ensuring end-to-end visibility. 4. Arrival Sorting and Final Deli...

As the aviation industry becomes increasingly globalized and technology continues to advance, the operation and maintenance of aircraft have grown more complex and efficient. Whether for ensuring aviation safety or reducing maintenance costs, improving aircraft management efficiency has become a critical task for airlines and their supply chain managers. In recent years, RFID (Radio Frequency Identification) technology, as a disruptive tool, has been increasingly applied to aircraft maintenance and spare parts management, greatly improving data tracking accuracy and significantly enhancing management efficiency and operational safety. 1. Introduction to RFID Technology RFID technology uses radio waves to transmit data, enabling the identification of items by reading information stored in tags without direct contact. In the aviation field, this technology can be used to attach RFID tags to aircraft components, tools, and maintenance records, enabling real-time tracking, management, and monitoring. An RFID system typically consists of three components: tags, readers, and a data management system. Tags are attached to components, tools, or equipment; readers are used to scan the tags from a distance; and the data management system processes, stores, and utilizes the data collected. 2. RFID Applications in Aircraft Spare Parts Management Aircraft spare parts vary widely and cover everything from engines to seats, and from fuselage structures to electrical systems. Each component must be maintained and replaced under strict standards and procedures. The tracking and management of these parts, in the past, relied on manual records and traditional barcode scanning, which involved many gaps and efficiency issues. The introduction of RFID technology in this area has significantly improved tracking management accuracy and efficiency. 2.1 Real-Time Tracking and Inventory Management By installing RFID tags on every spare part of an aircraft, airlines can achieve real-time tracking of these components. For example, when an aircraft requires routine inspection, maintenance personnel can simply use an RFID reader to scan the tags on the aircraft, quickly obtaining information about the component's usage history, production date, and maintenance records. This automated data collection process greatly improves the efficiency of spare parts management and reduces the likelihood of errors and omissions in manual data entry. At the same time, RFID technology plays a key role in warehouse management. For the storage and circulation of spare parts, RFID provides real-time inventory information, helping warehouse managers accurately monitor the location and quantity of components, avoiding issues like item loss or overstocking, and ensuring timely supply of parts. 2.2 Spare Parts Lifecycle Management The lifecycle management of aircraft components is crucial for ensuring safe operation. Every component has a strict usage lifespan limit. After a certain number of operat...

With the continuous advancement of technology and the increasing demand for entertainment experiences, RFID (Radio Frequency Identification) technology has been widely applied in various fields, particularly in enhancing the visitor interaction experience at theme parks and amusement parks. RFID not only improves convenience for visitors but also enables theme parks and amusement parks to achieve more efficient operations, ultimately providing visitors with a more personalized and immersive entertainment experience. This article will explore the various ways in which RFID technology enhances the visitor interaction experience and analyze its profound impact on the industry. 1. Overview of RFID Technology RFID (Radio Frequency Identification) is a technology that uses radio waves for object identification and data transmission. The core principle involves using radio waves for signal exchange, allowing tagged objects to communicate quickly and accurately with readers. An RFID system generally consists of tags, readers, and a data processing system. The tags contain microchips that store specific information, and the readers can communicate with the tags by reading their data within a short range. In theme parks and amusement parks, RFID technology has become an integral part of enhancing the visitor experience. From electronic tickets, fast-track access, personalized interaction experiences to queue management for rides, RFID is now indispensable in modern theme park operations. 2. Applications of RFID in Enhancing Visitor Interaction Experience 1. Electronic Tickets and Fast Track Entry Traditional paper tickets are not only prone to loss but also require long queues for entry, wasting valuable time for visitors. With the development of RFID technology, visitors can use RFID tickets or wristbands for quick, contactless entry. The RFID ticket, embedded with a chip, can be scanned at the entrance, automatically identifying the visitor and allowing them to enter without any waiting. This greatly improves efficiency and convenience. Moreover, RFID technology can be integrated with identity verification systems, allowing for more personalized services for visitors. For example, a visitor's photo, preferences, and previous visit history can be linked to the RFID ticket. When entering the theme park, the system can automatically identify the visitor and provide the staff with relevant data, ensuring a more personalized and high-quality service. 2. Smart Queue Management and Real-Time Feedback Queueing has always been a major challenge for visitors in amusement parks and theme parks, especially during peak times when the wait can be long and frustrating. RFID technology helps reduce waiting times and enhances the interaction experience for visitors. Many modern amusement rides are equipped with RFID technology, allowing visitors to receive real-time feedback on their wait times using electronic wristbands, mobile devices, or other RFID-enabled items. For...

With the increasing frequency of natural disasters, such as the recent strong earthquake in Myanmar, wildfires in Australia, and floods in Southeast Asia, the efficient and precise dispatch of emergency relief materials has become crucial. In April 2025, Myanmar experienced a 6.8 magnitude earthquake, which caused significant building damage and casualties, severely affecting local infrastructure. The rapid and accurate dispatch of materials post-disaster is critical to the recovery process. Traditional material management methods, reliant on manual records and inefficient logistics, are no longer sufficient to handle the scale and complexity of modern disaster responses. In this context, RFID (Radio Frequency Identification) technology has emerged as a powerful tool to improve material management and expedite relief efforts. RFID technology, with its real-time tracking, automated data collection, and transparency, is playing an increasingly important role in disaster response, especially in regions like Myanmar, where infrastructure is damaged and transportation is disrupted. It helps rescue teams achieve efficient and precise material distribution. Overview of RFID Technology RFID technology uses radio waves to identify and track objects. The RFID system consists of three main components: the tag, the reader, and the backend data processing system. Tags are attached to materials or assets and store key information such as type, quantity, and storage location. The RFID reader communicates with the tag via radio waves, transmitting this information to the backend system for processing and analysis. The main advantage of RFID technology lies in its ability to read data without contact and at high speeds, making it especially suitable for complex disaster environments. In situations like the Myanmar earthquake, where traditional methods often fail to provide timely information, RFID allows rescue teams to track materials in real time, reducing errors and delays in the distribution process. Applications of RFID in Disaster Response Material Tracking and Management After a disaster, the timely and accurate dispatch of materials is crucial. Following the Myanmar earthquake, many areas suffered severe damage to infrastructure, making traditional material distribution challenging. RFID can help ensure that critical materials like food, water, medicines, and protective gear reach disaster areas quickly and accurately. By attaching RFID tags to materials, rescue teams can track the movement of goods in real-time, preventing bottlenecks or misdeliveries. RFID helps logistics teams assess inventory levels quickly, ensuring that relief materials are replenished and dispatched in a timely manner. Fast Inbound and Outbound Inventory Management After a disaster, warehouse management must be highly coordinated and efficient. In the aftermath of the Myanmar earthquake, the swift entry and distribution of materials was a priority. RFID technology automates warehou...

Introduction Prison security management is a crucial component of the judicial system, involving inmate identification, behavior monitoring, asset tracking, and emergency response. Traditional prison management relies on manual patrols, surveillance cameras, and paper records, which are often inefficient and prone to delays and human errors. With the advancement of the Internet of Things (IoT), Radio Frequency Identification (RFID) technology is increasingly being applied in prison management to enhance security, optimize inmate supervision, and reduce operational costs. Applications of RFID in Prison Management 1. Inmate Identification and Real-time Tracking RFID technology enables precise identification of inmates. Each inmate can wear an RFID-embedded wristband or smart prison uniform, allowing the system to automatically record identity information, assigned locations, and movement patterns. Real-time Location and Restricted Areas: The prison management system can monitor inmates’ movements in real-time. If an inmate enters a restricted area without authorization, the system triggers an alert, notifying prison staff immediately. Preventing Escapes and Unauthorized Movements: If an inmate approaches prison walls or exits, the RFID system can integrate with access control and surveillance cameras to automatically secure the area and notify officers to take action. 2. Inmate Behavior Monitoring and Data Analysis By integrating RFID with prison management systems, authorities can track inmates’ daily activities and detect anomalies. Detecting Unusual Behavior: If an inmate remains in one place for an unusually long time or deviates from their expected routine (e.g., being absent from their designated bed at night), the system can issue an alert for officers to investigate. Conflict Prevention: RFID tags can analyze interactions between inmates. If historical data suggests a conflict risk between certain inmates, the system can prevent them from entering the same area simultaneously, reducing the likelihood of violent incidents. 3. Staff and Officer Management RFID enhances not only inmate supervision but also the efficiency and accountability of prison staff. Patrol Route Monitoring: Officers wearing RFID tags can have their patrol routes monitored to ensure they conduct security checks at the required times, improving patrol efficiency. Emergency Response: In emergency situations (such as violent altercations or medical emergencies), officers can use RFID-based authentication to gain rapid access to restricted areas, while the system automatically deploys nearby security personnel for swift intervention. 4. Asset and Weapon Management Managing assets and equipment is crucial for prison security. RFID can help track critical items such as keys, handcuffs, and weapons to prevent loss or misuse. Inventory Control and Tracking: Items like clothing, utensils, and books can be equipped with RFID tags to record usage, preventing unauthorized exchanges ...

In recent years, contactless services have rapidly developed worldwide, particularly in the restaurant industry, where smart and self-service solutions are becoming essential for improving operational efficiency and customer experience. RFID (Radio Frequency Identification) technology, with its high efficiency, accuracy, and automation capabilities, is emerging as a key enabler for smart restaurants implementing self-service ordering and checkout. This article explores how RFID facilitates contactless dining services and examines its applications, advantages, and future trends in smart restaurants. RFID is a wireless communication technology that uses electromagnetic waves to automatically identify objects and retrieve related data. Its core components include RFID tags, readers, and a backend management system. RFID tags contain a chip and an antenna, allowing them to store and communicate data with readers. RFID readers, available in handheld and fixed forms, read or write tag information. The backend management system processes, stores, and analyzes the data to enable intelligent management. Compared to traditional barcode technology, RFID offers faster identification, better anti-interference capability, and the ability to read multiple tags simultaneously, making it highly suitable for smart restaurant applications. Smart restaurants leverage RFID technology to automate the entire process from ordering to checkout, enhancing operational efficiency and customer experience. In self-service ordering, customers can use RFID-enabled smart menus. Each menu card has an embedded RFID chip, which customers can tap on a table-mounted or self-service terminal reader to browse the menu, select dishes, and place orders. The system can also record user preferences, providing personalized recommendations to enhance the ordering experience. For automated food collection, each dish’s tray or container can be equipped with an RFID tag containing information such as the dish name, price, and preparation time. When customers pick up their food, RFID readers automatically record their selection, reducing manual intervention and improving service efficiency. In smart checkout, RFID technology enables fast and contactless payment. Unlike traditional checkout processes that require manual billing, an RFID system automatically reads all dish tags on a tray, calculates the total price, and allows customers to pay via card or mobile payment. This method reduces wait times, enhances checkout efficiency, and lowers labor costs. RFID also plays a crucial role in precise inventory management. Restaurants can tag ingredients and food items with RFID to monitor stock levels in real time, optimize purchasing and replenishment plans, and minimize waste. Combined with temperature and humidity sensors, RFID helps track food expiration dates, ensuring food safety and improving quality control. Additionally, RFID supports smart membership and personalized services. Customers usin...

As global concerns over food safety, sustainable fisheries management, and aquaculture efficiency grow, the Internet of Things (IoT) is accelerating the digital transformation of the fishing industry. Among these technologies, Radio Frequency Identification (RFID) stands out for its efficiency, automation, and strong traceability. The application of RFID in aquaculture and catch tracking not only enhances management efficiency but also improves food safety and promotes sustainable fisheries. This article explores the applications, advantages, and future trends of RFID technology in aquaculture and catch tracking. 1. Fundamentals of RFID Technology RFID (Radio Frequency Identification) is a wireless technology used for contactless data identification and transmission. Its basic components include: RFID Tags: Chips attached to target objects that store relevant information. RFID Readers: Devices used to read or write information from RFID tags. Backend Systems: Platforms for data processing, storage, and analysis. Based on power supply methods, RFID tags can be classified into passive, active, and semi-passive types. Passive tags are cost-effective and suitable for individual fish identification, while active tags are ideal for long-range and underwater data collection. 2. Applications of RFID in Aquaculture 2.1 Individual Fish Identification and Health Monitoring RFID tags can be implanted or attached to fish, assigning each one a unique identification code, enabling precise individual management. In large aquaculture farms, RFID allows automated tracking of fish growth, vaccination records, and health data, reducing labor costs and improving farming efficiency. 2.2 Environmental Monitoring and Optimization RFID can be integrated with sensor networks to monitor key water quality parameters such as temperature, pH levels, and dissolved oxygen in real time. Tags can store fish population growth data in different water environments, and big data analytics can help optimize aquaculture conditions. For instance, intelligent feeding systems can adjust feed quantities based on RFID feedback, reducing waste and enhancing productivity. 2.3 Disease Prevention and Precision Medication By integrating RFID with intelligent aquatic disease management systems, infected fish can be quickly identified, preventing large-scale outbreaks. Additionally, RFID technology enables precision medication, ensuring specific fish populations receive the right dosage, thereby reducing antibiotic overuse and improving food safety. 3. Applications of RFID in Catch Tracking 3.1 Digitalized Fishing Operations Traditional fishing operations often suffer from inadequate record-keeping and lack of transparency regarding catch origins. RFID provides end-to-end traceability, recording real-time data on fish species, weight, time, and location during fishing trips. This enhances accuracy in fisheries management. For example, in large-scale ocean fishing, RFID systems on boats can automat...

Categories

New Products

JT-6210 0-1m UHF RFID Desktop USB Reader Writer ISO18000-6C Read More

JT-7100 0-3m 860-960MHz UHF RFID Industrial Grade RFID Reader Read More

JT-8380 0-6m UHF RFID 860-960MHz Middle Range Integrated Reader Read More

JT-P983 Industrial Tablet Pad RFID Handheld Reader Grade Long Range Android UHF Terminal Bluetooth RFID Reader For Warehouse Read More

JT-1550 Small Mini HF RFID 13.56MHz Module ISO14443A ISO 15693 Protocol Read More

JT-2302A 13.56MHz RFID Module ISO14443A ISO15693 Protocol Read More

JT-2302 HF RFID 13.56MHz Module ISO14443A ISO15693 Support Mifare1 IC card Read More

JT-2540 TM200 UHF RFID 4-port Module 860-960MHz TTL Read More

Copyright © 2026 Shenzhen Jietong Technology Co.,Ltd. All Rights Reserved.

IPv6 network supported