Call at :

+86 18681515767

Call at :

+86 18681515767

Email :

marketing@jtspeedwork.com

Email :

marketing@jtspeedwork.com

Call at :

+86 18681515767

Call at :

+86 18681515767

Email :

marketing@jtspeedwork.com

Email :

marketing@jtspeedwork.com

RFID technology to help Jingdong logistics to create the world's first unmanned sorting center

Recently, the world's first unmanned sorting center officially completed and operated successfully was unveiled - the unmanned sorting center of Jingdong Logistics Kunshan officially unveiled. This also marks the sorting out of Jingdong logistics and distribution into the audience unmanned, intelligent stage.

According to the introduction of Jingdong logistics sorting leader, compared to the traditional automatic sorting system that Kunshan unmanned sorting center is more intelligent. The field automation equipment coverage rate reached 100%.

For example, in the current cross-belt automatic sorter in the industry that the package (the package into the automatic sorting equipment for the package table) still requires manual operation. But in Kunshan unmanned sorting center has been automatically supplied Package and the package for six-scan to ensure that express documents are quickly identified by the sorting system access to use. And then it can achieve real-time effective sorting.

Kunshan unmanned sorting center is the biggest characteristic from the package to the loading and the whole process without personnel. In the current logistics industry that the entire warehouse distribution process, a single part of the "no one" model has gradually matured and put into use. But such as Kunshan unmanned sorting center that the entire sorting process of the entire link without People operate for the first time in the world.

Not long ago, Jingdong CEO Liu Qiangdong proposed that the forthcoming Fourth Retail Revolution is based on the Internet e-commerce, but also a revolution beyond the Internet and will bring humans into the smart business era.

However, the nature of retail in the future will continue to be centered on cost, efficiency and experience. The completion of the unmanned sorting center in Kunshan also significantly improved operational efficiency.

Currently sorting center sorting capacity has reached 9000 pieces / hour. Under the premise of the same site size and picking volume. It is estimated that each site can save 180 manpower. At the same time, the operational efficiency and operational quality of first-line equipment have also been significantly improved.

Compared with traditional supply capacity, the efficiency of automatic packet-packing can reach more than 4 times the traditional efficiency.

The main system of the unmanned sorting center in Kunshan is a customized and intelligent equipment management and control system independently developed by Jingdong R & D department - DCS intelligent management and control system, which includes automatic sorter control, unmanned AGV handling dispatching, RFID Information processing.

The audience of all mission instructions have DCS system hub control. Among them, the audience input 25 unmanned AGV (handling forklift), through the AGV scheduling system, the completion of handling, vehicle safety, avoidance, priority tasks such as the implementation of the country's first before and after the end of the unmanned AGV automated loading, Unloading operation of the operation.

In recent years, in the logistics of automatic sorting technology that the most commonly used to belong to the RFID technology. One of the most used forklift pallet applications, AGV trolley trackless guidance.

As we all known, AGV refers to unmanned vehicles equipped with automatic guidance devices such as electromagnetic or optics, which can be guided by prescribed routes with safety protection and various slashing functions. Specific application is that when a workshop needs accessories by the staff to the computer terminal input relevant information, the computer terminal and then send the information to the central control room, a professional technical staff to the computer instructions, cooperation in electronic control equipment .The order was eventually accepted by the AGV and executed - the accessories arrived at the appropriate location.

Currently, the most commonly used solution in the AGV industry is the location identification scheme using RFID tags and RFID sensors. Among them, AGV car navigation reader is an essential application equipment.

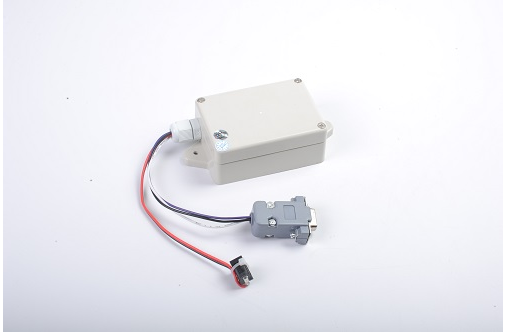

Shenzhen Jietong Technology has been focusing on the development, production and sales of AGV car navigation reader (RFID reader). The core R & D personnel of the technology team all have more than 10 years of RFID industry experience.

Categories

New Blog

Copyright © 2026 Shenzhen Jietong Technology Co.,Ltd. All Rights Reserved.

IPv6 network supported