Call at :

+86 18681515767

Call at :

+86 18681515767

Email :

marketing@jtspeedwork.com

Email :

marketing@jtspeedwork.com

Call at :

+86 18681515767

Call at :

+86 18681515767

Email :

marketing@jtspeedwork.com

Email :

marketing@jtspeedwork.com

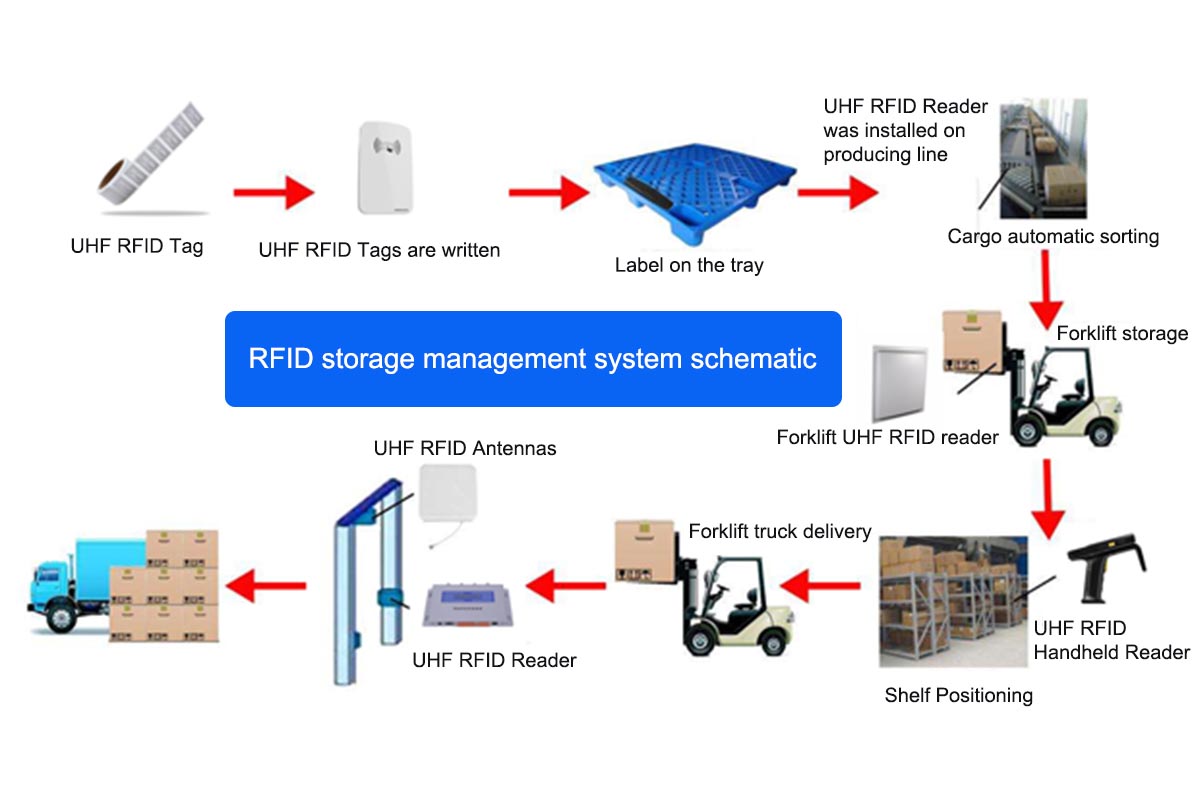

RFID in and out of storage management makes storage more efficient

The management of warehousing plays a very important role in various industries. The management of warehousing is related to every work link and better grasps the current state of inventory materials. RFID technology automatically collects data from various operations such as warehouse storage, storage, transfer, and inventory, so that the data of all aspects of warehouse management is fast and accurate, and the data of warehouse management is timely and accurately provided. A strong guarantee. RFID in and out of storage management makes storage more efficient.

In the actual warehouse management process, the work is generally carried out from three dimensions of warehousing, management and delivery, to improve the accuracy of warehousing management and upgrade the warehousing management service:

In the actual warehouse management process, the work is generally carried out from three dimensions of warehousing, management and delivery, to improve the accuracy of warehousing management and upgrade the warehousing management service:

1. Goods storage

Through the RFID automatic sensing access control device at the entrance of the warehouse,UHF RFID Tag of the item is identified (UHF RFID Tag is bound for each inbound goods), the information of the corresponding item is found in the database and automatically input into the management system, and the system records The library information is verified and, if qualified, the inventory information is entered. If there is an error, an error message is displayed, an alarm signal is issued, and the storage is automatically prohibited.

2. Inventory management

Traditional warehousing often consumes a lot of manual work in the inspection, management and monitoring of goods after storage, and the information is difficult to guarantee accuracy. Through the identification system, the classified products are regularly checked, and the changes in the inventory of the goods are analyzed and presented in a timely manner in the warehouse platform. When the goods are displaced, the RFID tag system automatically collects UHF RFID Tag of the goods, finds the corresponding information in the database, and automatically records the information into the warehouse management system, records the product name, quantity, location and other information to check whether abnormal conditions occur. An abnormal instant alarm occurs to ensure the security of warehouse goods.

3. Commodity delivery

In the outbound link of the goods, the dolphins are identified by UHF RFID Tag, and UHF RFID Tag of the goods and the goods are scanned to confirm the goods and update the inventory. When the goods arrive at the exit channel, the identification system will automatically read the RFID tag and call up the corresponding information in the database, and compare it with the order information line. If it is correct, it can be out of the warehouse, and the inventory of the goods is correspondingly reduced; If an abnormality occurs, the warehouse management system will display a prompt message to facilitate the staff to perform immediate safety monitoring and exception handling.

RFID technology has non-contact, fast scanning, high recognition efficiency, not easy to damage, suitable for harsh environment, easy to operate, fast reading and writing speed, large amount of information storage, one card multi-purpose, anti-collision, secure encryption performance, repeat Features such as usability. The adoption of RFID technology greatly improves the efficiency and accuracy of entering and leaving the warehouse, realizes the identification without opening the box, greatly reduces the manual workload in traditional inventory management, and realizes the security of storage management with faster storage of RFID technology. Efficient and accurate.

Categories

New Blog

Copyright © 2026 Shenzhen Jietong Technology Co.,Ltd. All Rights Reserved.

IPv6 network supported